Navy researchers turn seawater into fuel

The 'game changer' process to create liquid hydrocarbons from the sea powers a scale-model WWII plane in a test, and could soon be powering a lot more.

It might not be cold fusion, but researchers at the Naval Research Laboratory have, on a small scale, tapped into what could prove to be a nearly unlimited source of fuel for air, sea and even land vessels.

Researchers at NRL’s Materials Science and Technology Division recently demonstrated a proof-of-concept for using seawater to create liquid hydrocarbon fuel that was able to power a plane on a sustained radio-controlled flight, NRL said. True, the plane was a scale model of the World War II-era P-51 Mustang, so the process is a long way from powering fighter jets from aircraft carriers. But on the other hand, unlike cold fusion, it’s real—and could be available for commercial use in a decade.

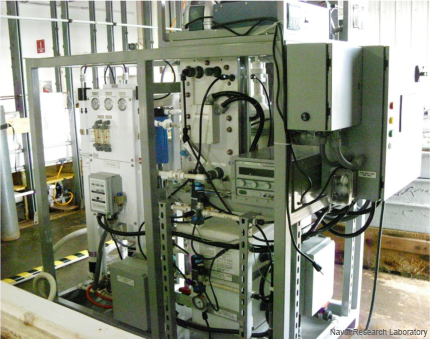

The system uses NRL’s proprietary electrolytic cation exchange module (E-CEM) to remove carbon dioxide from seawater at 92 percent efficiency, while at the same time producing hydrogen, NRL said. A metal catalyst in a separate reactor system then converts the gasses into liquid hydrocarbons, which are then used to fuel the plane.

This is the first time fuel synthesized from the sea has been used to power an internal combustion engine, a breakthrough that could have significant implications for the military, as well as for commercial use.

The process is “a game changing technology for extracting, simultaneously, CO2 and H2 from seawater," said Dr. Heather Willauer, NRL research chemist. "This is the first time technology of this nature has been demonstrated with the potential for transition, from the laboratory, to full-scale commercial implementation."

Ultimately, the technology could allow ships to remain at sea longer without refueling. Only aircraft carriers and submarines have nuclear propulsion. The lab-scale reactor systems used in the test could be scaled to commercial modular reactor size by increasing the length and number of reactors, NRL said, which would increase capacity.

The E-CEM removes carbon from seawater while also producing hydrogen.

One reason the process is efficient is the composition of seawater, which has a high concentration of carbon dioxide, making the conversion process possible without adding any chemicals or other substances. And NRL said the liquid contains hydrocarbon molecules in the carbon range--C9 to C16—that would be suitable for jet fuel as well.

NRL projects that the cost of liquid hydrocarbon jet fuel created through this process would be $3 to $6. If the lab can draw enough funding and partnerships, the technology could be commercially available in seven to 10 years, NRL said.