New technology looks deep to identify counterfeit microchips

The Advanced Scanning Optical Microscope works at the nanometer level to help ensure the reliability of integrated circuits.

Efforts to prevent counterfeit electronics from finding their way into military systems have ranged from plans to add a tell-tale dielet at the point of manufacturing, to using plant DNA to confirm authenticity, to a Defense Department rule issued in May that puts the onus on supply-chain contractors.

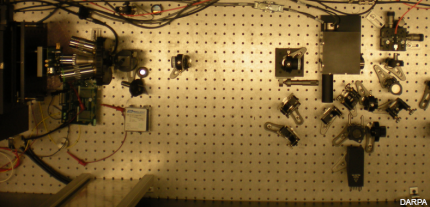

DOD researchers have added one more tool with a technology designed to help engineers perform forensic analysis on microelectronics, including integrated circuits confiscated by law enforcement. Researchers SRI International, working under a contract with the Defense Advanced Research Projects Agency, have delivered an Advanced Scanning Optical Microscope to the Naval Surface Warfare Center (NSWC) in Crane, Indiana, DARPA said in a release.

The microscope, developed as part of the agency’s Integrity and Reliability of Integrated Circuits (IRIS) program, works at the nanometer level, scanning integrated circuits with an extremely narrow infrared laser beam to reveal information such as how a chip was constructed and what function circuits at the transistor level performed, DARPA said.

The microscope is one of many technologies developed under the IRIS program, all aimed at ensuring the reliability of integrated circuits. It adds another important layer of hardware assurance, Kerry Bernstein, DARPA program manager, said in the release. “These tools are optimized to support the mission of ensuring trust in microelectronics in DOD labs such as NSWC Crane.”

The market for integrated circuits, used in computers of all kinds, has ballooned in recent years, DARPA noted. It grew by 20 percent from 2012 to 2013 alone, reaching a worldwide total of $231 billion. But most chip production takes place overseas, outside of any U.S. regulatory arms. The fact that the U.S. military accounts for only 1 percent of the market also limits its ability to influence manufacturing. So DOD’s focus has been on securing the supply chain.

The rule DOD issued in May requires electronics contractors to maintain procedures for detecting and avoiding counterfeits and submit to audits to confirm those processes are in place.

With its growing reliance on high-tech systems, DOD has plenty of motivation to ensure the authenticity of integrated circuits and other electronics parts, which are used in every kind of weapon, surveillance and communications system. And there is plenty of evidence that, left unchecked, counterfeit parts could wind up in military systems.

In May 2012, the Senate Armed Services Committee said that it found more than 1 million suspected counterfeit parts in the supply chain intended for "critical" military systems, including the Air Force’s largest cargo plane, Special Operations helicopters and a Navy surveillance plane. The committee’s report said the vast majority of the parts were manufactured in China.

“Our report outlines how this flood of counterfeit parts, overwhelmingly from China, threatens national security, the safety of our troops and American jobs,” Sen. Carl Levin, D-Mich., the committee’s chairman, said at the time. “It underscores China’s failure to police the blatant market in counterfeit parts – a failure China should rectify.”

Short of China rectifying the failure, programs like IRIS and technologies like the Advanced Scanning Optical Microscope will remain necessary.