Nanotech process a breath of fresh air for submarines

The SAMMS technology offers an environmentally safe way to purify the air without the bad smell and hazardous waste created by the current system.

Originally designed to remove mercury and other contaminants from groundwater, SAMMS nano materials have been adapted to clean submarine air of carbon dioxide.

Sailors aboard the Navy’s submarines could soon breathe a little easier—and smell a little better—thanks to a nanotechnology system developed at the Pacific Northwest National Laboratory.

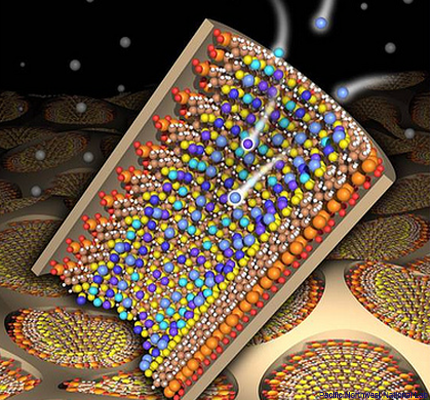

The technology, called SAMMS, for Self Assembled Monolayers on Mesoporous Supports, is a dry system using hybrid nanoporous materials that can capture carbon dioxide from the air during shipboard purification. And it can replace the current liquid process that is corrosive, creates hazardous waste and smells bad.

Purifying the air is an essential part of submarine operations, of course. Unfortunately for those aboard, the best solution to date has been a system using amine, a liquid that extracts carbon dioxide from the air but has its consequences. Writing in Wired, Nick Stockton, who served on a sub for three years, said it is a smell of “old diesel mixed with a dash of sulphur” that clings to everything, including clothing and sailors themselves. The liquid also corrodes materials and creates organic solvent waste that requires careful handling.

SAMMS, on the other hand, offers an environmentally friendly of cleaning the air without the olfactory side effects. It’s made of layered nano materials with pores capable of drawing in large amounts of carbon dioxide. When full, a little heat or a vacuum can be used to release the carbon dioxide, allowing for reuse of the material. And when it’s eventually used up, it can be disposed of as non-hazardous waste.

Research into SAMMS dates back at least a dozen years, although rejuvenating air aboard submarines wasn’t the original idea. PPNL first developed and used a version of it for removing mercury and other heavy metals from contaminated groundwater.

Later, PNNL worked with Naval Surface Warfare Center’s Carderock Division, Ship Systems Engineering Station and the Naval Sea Systems Command on building a prototype for use aboard submarines. In 2012, the project won an Interagency Partnership Award from the Federal Laboratory Consortium for creating an entirely new, environmentally friendly method of air purification.

Crews on current submarines apparently will have to live with the air purification systems they have because of the difficulty of removing and replacing existing systems, but PNNL said the technology could be used on future submarines as they join the fleet. It also could have other uses, such as in rebreather Scuba gear, space vehicles, space suits, or even to cut heating and cooling costs in buildings by reducing the exchange of air from outdoors.