The military is making big plans for nanoscale materials

HRL Laboratories, a joint venture of Boeing and General Motors, is developing processes to assemble strong, extremely lightweight nanoscale materials for DOD systems

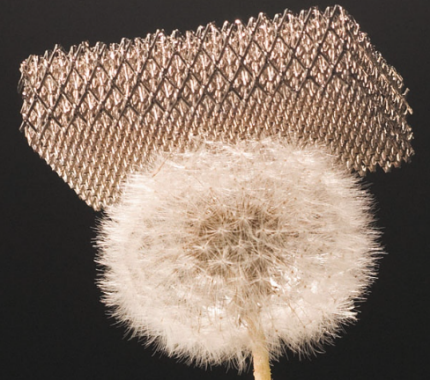

Boeing calls HLM's microlattice the lightest metal ever.

A corporate R&D laboratory jointly owned by Boeing and General Motors said it plans to develop new methods for scaling up atomic-scale materials to exploit their unique properties.

HRL Laboratories of Malibu, Calif., also said Tuesday it would develop processes to assemble nanoscale materials into millimeter-scale components that are compatible with existing manufacturing technologies. An HRL team will work with Intelligent Materials Solutions Inc. of Princeton, N.J., to assemble nanoscale particles used to create finished components that would be 1 million times larger than individual nanoscale particles, HRL said.

The work is being funded under the Defense Advanced Research Project Agency's Atoms to Product (A2P) program. The Air Force Research Laboratory is also funding the nanoscale manufacturing effort.

HRL also is working under NASA's Game Changing Development Program to develop a microlattice material developed at the nanometer scale, that is one-tenth the weight of carbon fiber while remaining strong and flexible. The material, which Boeing has called the lightest metal ever, would reduce the mass of future space craft by 40 percent and would be essential on a trip to Mars. It also could be used in the structural components of aircraft—and considering General Motors’ involvement, ground vehicles—which would save a lot on fuel costs.

The DARPA program seeks to leverage the "very uncommon physical characteristics [of common materials] when fabricated at nanometer-scale." Among the potential military applications are quantized, or variable, current-voltage behavior, dramatically lower melting points and much higher specific heats (the amount of heat required to change the mass unit of a substance by one degree in temperature).

Along with atomic-level assembly of these materials, the A2P effort also seeks to leverage unique material properties for miniaturization, 3D components and other nanometer-scale assembly.

The A2P program also reflects DARPA's efforts to reduce the cost and complexity of manufacturing weapons. A related agency effort detailed in September seeks to develop new composite materials and processes for manufacturing small parts. The goal is to improve weapon performance while compressing tool development and fabrication cycles.

HRL said its goal under the A2P program was to "develop a rapid, fundamentally new method that enables intricate 3-D millimeter-scale components made from a wide selection of nanoscale elements."

The laboratory noted that current nanoscale fabrication techniques such as vacuum deposition, which is used to deposit atoms on substrates below atmospheric pressure, are limited in terms of speed and the ability to scale to millimeter dimensions.

The former Hughes Research Laboratories established in 1948 specializes in research on sensors and materials, microelectronics and electromagnetics. It currently serves as a Defense Department "trusted foundry" certified to manufacture electronic components for DOD and the National Security Agency.